Research and Development Projects

| Industrial project | |

Research based on failure analysis and reliability investigations to significantly increase the quality of electronic products Description: Aim: Projects aimed at the research of surface mount technology processes at electronic production by failure analysis and reliability investigations. The failure mechanisms revealed by the analyses might significantly increase the reliability of new product versions. Results: The knowledge accumulated during the research is mainly concentrated on the solderability of printed wiring boards and components. There are many factors affecting wettability and thus the quality of the solder joint. For example: acceptability of surface finishes, contaminations and several production technology parameters. Research results had been continuously fed back to the industrial partners financing the projects. This led to successful development of product and production processes. Project Leader: Péter Gordon | |

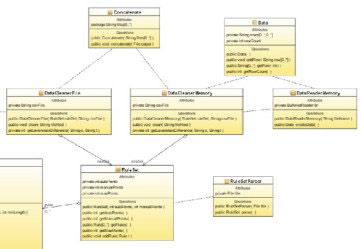

Researching data clearing algorithmsand development of a data clearing method Description: Aim: Analysing the customer data provided by the sponsor to estimate general data quality. Furthermore the project proposed an approach to detect data quality failures and a complex method containing algorithms to eliminate them. Results: During the research the provided data have been deeply analysed. IT has been stated that the quality of the stored data is rather varying depending on the date of storing and the type of its source application system. The failures were classified and different solutions were provided for the detection and the elimination for each class. The main focus was set to the detection and elimination of duplicated entries where a half-automated solution was provided as the main result of the researches. Project Leader: Péter Martinek | |

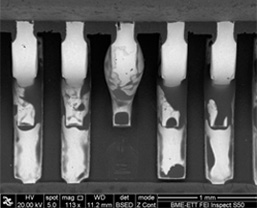

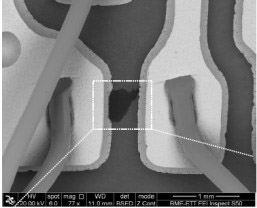

Investigation and analyses of occasional quality problems in the automotive electronics industry. Description: Aim: Investigate and analyse occasional quality problems in the automotive electronics industry by failure analyses methods and reliability tests such as scanning electron microscope and energydispersive x-ray spectroscopy; x-ray structural analysis; crosssectioning, etc. Evaluation of the results and making final conclusions. Results: Investigate more than 100 production failures and raw materials of production in every year. Build a knowledge base about the most frequent problems of the automotive electronics such as: contamination on the soldering surfaces, bonding pads, etc..; soldering failures; surface finishing problems of the PCBs; unknown material detection and analyses; corrosion problems and electrochemical migration; wire bonding failures. Study the quality and reliability problems of the products prepared by costumer. Support the costumers with electronics and material science expertise. Project Leader: Balázs Illés | |

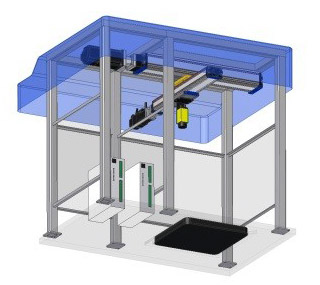

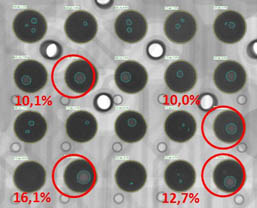

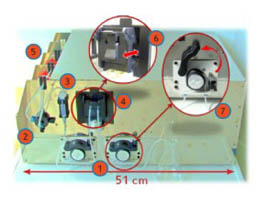

Research and development of automatic optical end control hardver and softver system for PIN insertion processes Description: Aim: Development of new experimental method for non-contact examination of connector PINs and connector houses. Requirements are the highly reliable identifications of the tilted or missing PINs. Results: Optical control of tilted, missing PINs according to the connector house dimensions. Logfile record, sending and registration. Specific Barcode and DMC (Data Matrix Code) identification and SPC (Statistical Process Control Cycle time, including operator assistance. Project Leader: László Jakab | |

Investigation the effect of the surface-finishes, fluxes and solder mask on electrochemical migration. Description: Aim: Study the effect of different soldering materials in different combination on the phenomenon of electrochemical migration. The following soldering materials were investigated: four surface finishes (OSP, iSn, HASL (SnPb) and bare Cu); four fluxes; and PCBs with solder mask (only one solder mask method) and without solder mask. All together 28 different test combinations were examined. Results: Special measurement setup was designed for the experiments. During the measurements it was observed that the iSn and HASL samples contain more water molecules or OH groups (perhaps chemically bound) on the surface than the bare Cu and OSP samples. The water or OH groups can adsorb the water molecules from the gas phase easily on the surface of the sample during the THB test and due the proton conductivity of the water can cause the SIR drop that we encounter. On the other hand, on bar Cu samples a continuous water film should be present for getting SIR drop. The baking process according to the DIN-32513 standard and the reflow profile was not enough. The baking process at 150ºC/16h was enough on the non-fluxed samples but the fluxed samples needed an additional drying. Project Leader: Gábor Harsányi | |

Design and manufacturing of Printed Wiring Boards Description: Aim: Production of different Printed Wiring Boards according to documentation coming from industrial partner. These substrates are used in development of electronic circuts. Researches and analyses, evaluation of construction problems of display moduls are in the focus of cooperation and developing new circuits and accompanied production technologies. Results: During the cooperation period we have designed and manufactured special substrates for electronic products of the costumer and examined the production technologies applied for producing different substrates. The obtained results and our other experiences have conducted us to take part in the improvement of technology and construction of electronic circuits, this way we have supported the costumer with our knowledge about the electronics manufacturing, concentrated to the related technical and economical aspects. We have supposed possible development and optimization methods for the costumer. Project Leader: László Gál | |

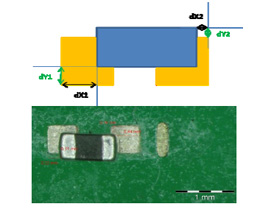

Research and development on testing and assembling electronic module circuit prototypes Description: Aim: Researchingthe key steps of surface mount electronics technology: electrically conductive adhesive technology (newmethods to cure isotropic conductive adhesive in infrared and vapour phase ovens) and investigating the accuracy of automated component placement (equipment characterization).The economic applicability and the effectivenessof production plays extra importance because of their high influence on the quality and reliability of the module circuitsto be produced. Results: Initialtests and experiments were made to define component mounting accuracy ofthe newly arrived TWS Quadra DVC Evo automated assemblingmachine, also in comparison to the existing machine.Statistical analyses were madespecifying placement accuracies in X, Y andΘorientationsfor both machines. During the research on the technology of electrically conductive adhesives -an alternative method to soldering technology -. we have definedcuring parameters with which we realized electrically conductive adheredjoints whose mechanical strength were acceptable in normal functioning conditions. Projekt Leader: Miklós Ruszinkó | |

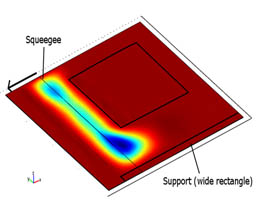

FEM simulation of elastic deformation of stencil on the typical PCB surface Description: Aim: The topography of the PCB surface has a high level of variation in the vertical dimension. Since the solder resist on the ground is much lower in comparison with the solder resist on the copper. These protruding areas can keep-off the stencil from the surface of the PCB leading to soldering failures. The aim of the researchis to have a closer look on the local elastic deformation behaviour of the stencil during printing process, and to analyse possible stencil distortions due to squeegee pressure and theireffect on the printing quality. Results: During the research we have carried outinvestigationon the stencil bending during the printing process. A FEM model has been created which can predict the necessary distance from a protruding area on the PCB surface to obtain a full stencil bend-down and to eliminate the so-called “gasketing” failure.The minimum technological distance (TD) between fine pitchpads and the pattern causing the level differences on the bareboard can be added as a design guideline for Printed Wiring BoardsCAD software. Furthermore if the necessary distance cannot bekept due to the high density of the electronic circuits, the extentof the required stencil aperture volume reduction can also be definedbased on our results. Project Leader: László Jakab | |

Új gyártási eljárások kifejlesztéséhez szükséges tudásanyag megszerzésére irányuló kutatás, nagymegbízhatóságú autóelektronikai termékek hibaanalitikai és megbízhatósági vizsgálataival Description: Aim: Researches and analyses on automotive electronics which have production failures or malfunction (observed by the end user). The automotive electronics are supported by the costumer. Find relations between the studied production failures and the quality of the production technology in order to improve the yield of the production and develop new production technologies. Results: During the research we have carried out special failure analyses and reliability investigations on the products of the costumer and examined the production methods applied by the costumer. The obtained resultsand our other experiences (earned during the previous cooperation with the costumer) have conducted us to the root causes and effect mechanism of the studied problems. In this way we have supported the costumer with our knowledge about the electronics manufacturing and the quality insurance, concentrated to the related technical and economical aspects. We have supposed possible development and optimization methods for the costumer. Project Leader: Balázs Illés | |

| EU fundig project | |

Provision of a European Training Infrastructure FP7-ICT-2011-8 No. 316526 Description: Purpose: The objective of the EuroTraining project is to provide a European Training Infrastructure facilitating the provision of high calibre training across Europe. The structure will support professional advancement training as well as academic training. Professional course providers will get a central place for the presentation of their training offer while academics will get a course material exchange service targeting graduate nanoelectronics schools. The training action will enhance the development of the European knowledge-based society in the field of nanoelectronics. Results: The project has not been completed yet, but we have organised Train-the-Trainer courses, identified and qualified international networks and self-training materials regarding nanotechnology, nanosystems and nanoelectronics. Besides, new website, Facebook and Twitter pages have been created to strengthen the social media appearance of the project. Website: http://www.eurotraining.net; Consortium partners: FSRM (CH), TUD (DK), COREP (IT), CEA-LETI (FR); Project Leader: Olivér Krammer | |

Developing Integrated Electronic Components With Nanotechnology Solutions KMR12-1-2012-0406 Description: Purpose: The production and use of soft magnetic nanostructured materials as integrated components. In the case of FR4 substrate utilization the goal is to increasing the use of space, for built-in volume and space-saving components. Most importantly, the largest mass component chosen as the inductor. It can significantly reduce the weight and size of the surface to be used for soldered components. Results: The project has not been completed, but we have created the first prototypes. We have successfully integrated an inductor to FR4 substrate. It is important to highlight as a result that a high cut-off frequency and relatively high inductance value was achieved. Consortium partners: HITELAP (HU), BAY (HU); Project Leader: Richard Berenyi | |

Virtual and Practical Applications to Electronic Assembling Technology 2013-1-TR1-LEO05-47531 Description: Purpose: The main aim and objective of this project is to create a training module about electronic assembly technology to educate the managers/employees of SMEs about electronic assembly technology systems in industry. It is proposed to get a training package (possibly for two weeks) which can be applied to those target groups which is created according to special needs of Turkish market and Turkish vocational education system. Moreover, we would like to prepare a technical laboratory which contains either/both electronic assembly technology in 3D in context of this project. Results: The project has not been completed yet, but we have identified the training materials which will be transferred with the control of the Turkish coordinator. Besides, those machines have been identified too, which operation will be presented in 3D animations. Consortium partners:TOU(TR), UPB-CETTI(RO), TUKE(SK), ODEM(TR); Project Leader: Oliver Krammer | |

Deep Vein Thrombosis-Impedimetric Microanalysis SystemDVT-IMP FP6-2005-IST-5-34256 Description: Aim: The obejctive of the DINAMICS project is to use micro-and nanotechnologies to develop an integrated and cost-effective nanobiologicalDNA/RNA sensor system for detection of bioterrorist and attacks on water supply systems. Lysis refers to the disruption of a cell or virus namely breaking the cellular membrane or protein capsule, causing the DNA and RNA contents to spill out by enzymatic, chemical, physical or electrical mechanisms that compromise its integrity. Results: Our device uses physical and electrical mechanisms for a more automatisable cell lysis than the gold standard enzymatic method. Consortium partners: BHR Group Limited (UK), Budapest University of Technology and Economics (HU), Cranfield University (UK), Hemosoft Ltd. (TUR), I.D.E.A. s.r.l. (I), Lambda GmbH (A), Lionix BV (NL), MikroMikoMed Kft (HUN), Provenion GmbH (DE), Steinbeis-Europa-Zentrum (DE), University of Bologna (I), Water Research Institute (SK); Project Leader: Hunor Sántha | |

Provision of a European Training InfrastructureFP7-ICT-2007-CSA No. 211806 Description: Purpose: The objective of the EuroTraining project is to provide a European Training Infrastructure facilitating the provision of high calibre training across Europe. The projectconsists of:1.A continuing training programme with twoimportant assets:the European Course Directory and the Quality Labelling service.2.An action to support graduate schools in micro-and nanoelectronics with courses, workshops and training material.3.All services offered will be gathered in the European Training Infrastructure web site, promoting the training services and attracting participants. The website will contain updated information on Train-the-Trainers programmes, Qualified Bank of Internet Links,training market intelligence, etc. Results: EuroTraining has developed training roadmaps describing the requirements with respect to industrial training needed when adopting nanoelectronics and nanosystems.The major conclusions are that stimulation of course provision is needed in areas like nanoscience and nanotechnology. Training is needed for all ages (school, graduate, post-graduate). Special attention is needed for actions on teachers’ training (train-the-trainers) and educational materials (e.g. use of Internet and course sharing). Consortium partners: Technoconsult(DK), DTU(DK), COREP (IT), BME (HU), CEA-LETI (FR); Project Leader: Zsolt Illyefalvi-Vitéz | |

E-Learning Education and Continuing Training to Electronics Assembling Technology Description: Purpose: The main aims and objectives of the project are to adapt and integrate the innovative content and results already existing at some universities of Central East European region acquired partly from previous Leonardo da Vinci Projects and partly from other innovative projects into a public, multi-lingual training system. Trainees and teachers of vocational education schools; institutions, associations, enterprises working in the electronics assembling field, as well as, bodies providing guidance, counseling and information services relating to lifelong learning can make good use of virtual training facilities. Results: The following tangible products(R1, R2, R3 and R4), their applications and their analyses:R1. The Virtual EMS Factory, a virtualized typical Electronics Manufacturing Service Factory.R2. EAT e-learning program with the most important topics of Electronics Assembling Technology(EAT).R3. EAT Certified Assessment Option using self-assessment tools. R4. Statistics of indicators and impact factors. Website:http://elect2eat.eu; Consortium partners: BME (HU), DRKK (HU), ERAK (HU), UPB-CETTI (RO), ARIES (RO), STPKC (SE), TUKE (SK), SPSE (SK); Project Leader: Zsolt Illyefalvi-Vitéz | |

An integrated modular service for mixed microtechnologymicroBuilder FP6-2007-IP-027175 Description: Aim: The goal of microBUILDERis to increase the commercial success and competitiveness of European industry by facilitating the introduction of new microtechnology to key components in products. microBUILDER provides industry with a simple and cost-effective access to mixed technology development and manufacturing and supports customers from the first idea to a final product. SMEs, but also academic research groups, are the target user group. Results: Since April 2006 the microBUILDER consortium has established flexible manufacturing services for polymer-based and silicon-based microsystems. The funding by the European Commission has now come to an end. The developed technologies and design services will still be available except forthe MultiMEMS MPW, which will be continued as a more flexible custom process.Customers can address an inquiry directly to the partner offering the technologyof interest. Inquiriesfor the microBUILDER Design Handbook can be directed to SINTEF. Website:http://www.sintef.no/Projectweb/Microbuilder; Consortium partners: Sintef (NO), SensoNor(NO), Vesstfold University College(NO), Institut für Mikro-und Informationstechnik(DE), thinXXS Microteshnology GmbH (DE), Consorcio per la Ricerca e l'Educazione Permanente (IT), Conventor (FR); Project Leader: Richárd Berényi | |

Establishment of Microsystems training requirements in EuropeFP7-ICT-2007.3.6: No:223849 Description: Purpose: The objective of the EuroTraining project is to provide a European Training Infrastructure facilitating the provision of high calibre training across Europe. The training action will enhance the development of the European knowledge-based society in the field of smart systems.The EuroTraining-MST action will offer access to a comprehensive range of advanced training courses, course material for European micro/nanosystems,university programmes and employee training support. Special attention will be devoted to develop and make available courses supporting the next-generation smart systems,theconvergenceofmicro/nano/bio-technologies,theintegration of smart materials and smart systems for communications and data management. Results: EuroTraining-MST:facilitatedtraining across Europe by theEuropean Training Infrastructure with more than 400 annual courses; providedmarket requirements and training roadmaps; promotedprofessional advancement training; organizedcontinuing training courses in subject areas not yet covered by the market; provided upgraded knowledge to engineers and improved practical skills for industry; maintainedand extendeda European quality labeling schemefor continuing training. Website:http://www.eurotraining.net; Consortium partners: FSRM (CH), DTU (DK), Technoconsult(DK), COREP (IT), BME (HU), CEA-LETI (FR); Project Leader: Zsolt Illyefalvi-Vitéz | |

Rapid SPR for parallel detection of pathogens in blood(SP5A-CT-2006-044515) Description: Aim:Afast, cheap and at the same time very sensitive method, which has the potential to detect many different blood pathogens simultaneously. A new type of surface plasmon resonance (SPR) transducing principle is exploitedforthesimultaneous detectionof the pathogens HIV, hepatitis C, hepatitis B and syphilis. Theplatformenables detection of thepresence of any blood pathogensafter customisationof100 sensor sites. Results: Our Surface Plasmon Resonance imaging (SPRi) offers a new generation in the label-free analysis of bio-molecules, providing information on kinetic processes (association and dissociation), binding affinity and even concentration or real-time target molecule detection. We developed a small, fixed-angle SPR imaging device that enables the biochips to be prepared in an array format with up to 100 active sites (spots) on a 10 x 10 mm area providing SPR information simultaneously. Consortium partners: Fraunhofer Society, Institute for Biomedical Engineering (FhG-IBMT), Germany; University of Birmingham, UK; Lausitz University of Applied Sciences, Germany; The Holding Company for Biological Products and Vaccines, Egypt; MikroMikoMed Ltd., Hungary; Institute for Analytical Sciences Dortmund, Germany; Analytical Micro-Systems Department of Mivitec GmbH, Germany; V. Lashkaryov Institute of Semiconductor Physics, National Academy of Sciences of Ukraine; Budapest University of Tecnology and Economics; Project Leader: Hunor Sántha | |

SPE_SAFE -Microfluidic device for specimen on-site stabilization by extraction with self-reporting quality control data monitoring Description: Aim: The objective of our SPE-SAFE project is to develop a cheap, mobile device for extrac¬tion and stabilization of samples. • Sample: biological sample (blood, smear, spit, urine)• Extraction: retrieve DNS/RNS contant of cells presents in the sample• Stabilization: fixing the retrieved DNS/RNS, that qualifies them for long time storingThe concept contains two-level quality assurance system. 1. Before & after transport, multiparametric, PC supported 2. During transport, low power, built into the cartridge. Results: The SPE-SAFE is a handheld device which performs the procedure in microfluidic cells mentioned above. The stabilization is a manual algorithm, which is performed by the specialist nurse, using the device. The stabilized DNS/RNS samples are stored in the cartridges. The sample is transported this way to the genetical laboratory, where it will be diagnosed. BME-ETT Sensors and Microfluidics Laboratory developed: 1. proprietary manufacturing processes, 2. • system design, 3. microfluidic components (valves, reaction chambers, mixers, macro-micro interfaces), 4. flowmeter with PCB technology, 5. electronics. Consortium partners: Semmelweiss Egyetem, BME Elektronikai Technológia Tanszék, Genoid Kft.; Project Leader: Hunor Sántha | |

Copyright © Budapest University of Technology and Economics (BME) |